We’re here to help! Whether you have questions about our businesses, technologies, career opportunities, or want to explore partnership opportunities, our team is ready to assist you. Simply fill out the form below, and we’ll get back to you as soon as possible. We look forward to connecting with you!

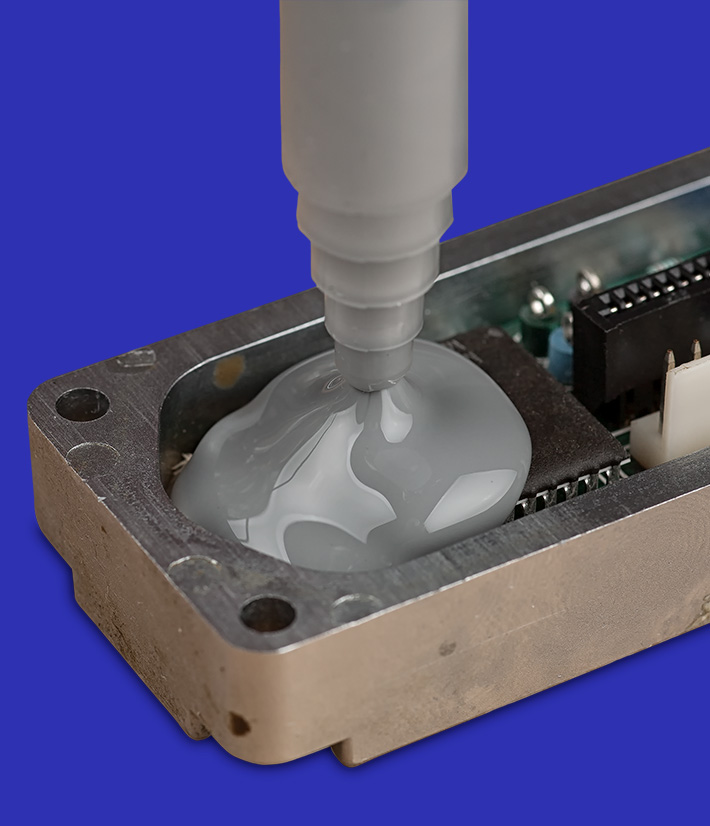

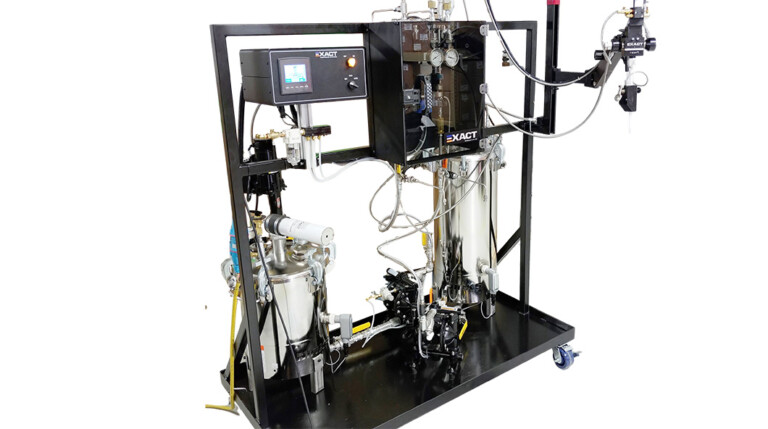

EXACT Dispensing – Precision Meter Mix Dispense Systems

EXACT Dispensing Systems provides dispensing solutions for single and plural component reactive formulations.